What factors determine berth capacity at a terminal?

Understanding berth capacity: The backbone of terminal efficiency

Berth capacity represents the maximum number of vessels that can be serviced at a terminal’s quayside within a specific time period. It’s the foundation upon which all terminal operations are built and directly influences the entire logistics chain’s efficiency.

When planning container terminals, berth capacity calculations are essential for determining how well a facility can meet current and future demands. A terminal with insufficient berth capacity creates bottlenecks that ripple throughout the supply chain, causing vessel waiting times, congestion, and increased costs for shipping lines and cargo owners alike.

Berth capacity at a terminal is determined by a combination of physical infrastructure, vessel characteristics, operational efficiency, and technological integration. The key factors include:

- Quay length

- Water depth

- Vessel size and call frequency

- Crane productivity

- Labor efficiency

- Yard operations

- Equipment availability

- Terminal operating systems

When these elements work together optimally, they create a balanced system that maximizes throughput while maintaining service levels. A terminal’s berth capacity directly impacts overall efficiency and is often the primary constraint in the terminal operation chain.

Understanding the relationship between berth capacity and other terminal subsystems is crucial – even the most efficiently designed yard will underperform if berth operations cannot keep pace with container flow requirements.

What physical factors affect berth capacity at a terminal?

| Physical Factor | Impact on Berth Capacity |

| Quay length | Determines how many vessels can be accommodated simultaneously |

| Water depth | Determines the maximum vessel size that can be accommodated |

| Approach channel dimensions | Affects vessel maneuverability and access times |

| Quay structure | Load-bearing capacity, fender systems, and mooring arrangements influence handling capabilities |

How do vessel characteristics influence berth capacity planning?

Vessel characteristics have a profound impact on berth capacity planning and directly determine infrastructure requirements. The following factors are particularly significant:

- Vessel size – affects both physical space needed and handling resources required

- Call frequency patterns – regular vs. irregular schedules impact resource planning

- Cargo volume per call – larger exchanges require more handling time

- Vessel technology – modern vessels may have different mooring and service requirements

The trend toward larger container vessels presents significant industry challenges for container terminals. Ultra-large container vessels require longer berths, deeper water, and higher-capacity cranes. More importantly, they generate more concentrated workloads during each call, creating peak demands that the terminal must accommodate.

Call frequency patterns also influence capacity calculations. Terminals servicing regular liner services with predictable schedules can plan resources more efficiently than those handling irregular calls.

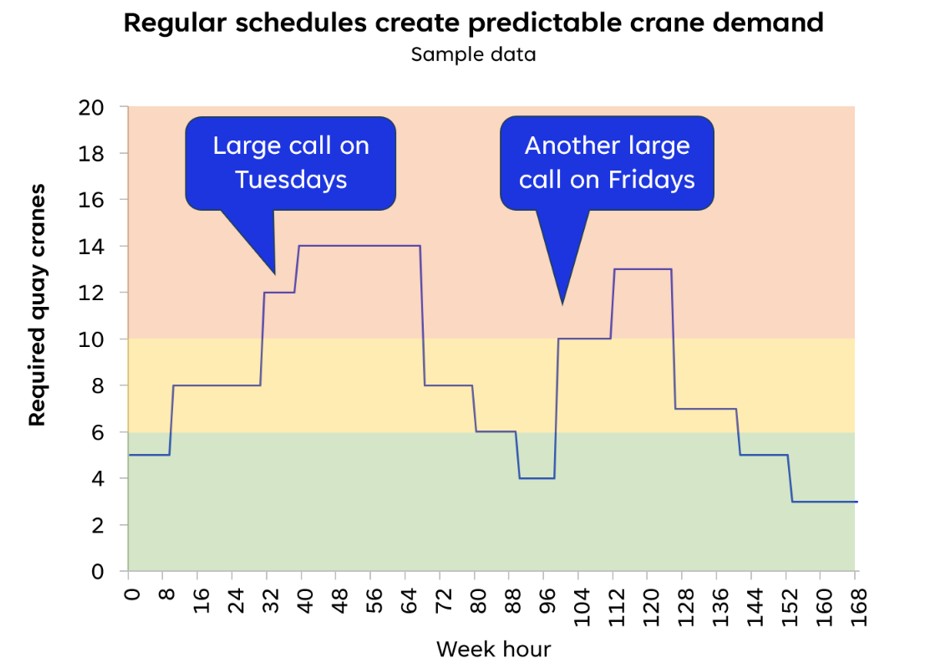

Figure 1. Quay crane demand based on weekly schedule

In this example, quay crane demand follows a clear weekly cycle. About one-third of the time, six or fewer cranes are active; another third requires 7–10 cranes; and the final third demands more than 10 cranes. With such a regular schedule, terminals can allocate FTEs efficiently, plan maintenance in quieter periods, and even attract additional volume when capacity is available.

The cargo volume per call affects how long each vessel occupies the berth. Larger exchanges require more handling time, reducing the number of vessels that can be serviced within a given period. As shipping alliances consolidate services, there are fewer port calls but with larger exchange sizes per call.

When planning for future berth capacity, it’s essential to consider the expected evolution of vessel characteristics in your market segment. For container terminals, this means preparing for larger vessels and more concentrated cargo exchanges that require greater peak handling capacity.

What operational factors determine maximum berth productivity?

Operational factors are the dynamic elements that determine how efficiently the physical infrastructure can be utilized:

- Crane productivity – directly influences vessel turnaround time

- Labor efficiency – skilled operators and effective work scheduling

- Yard operations – supports efficient container flows to/from quayside

- Equipment availability – reliability and redundancy strategies

- Maintenance programs – preventing disruptive outages during operations

The number of cranes deployed per vessel, their technical specifications, and operational performance all contribute to quayside productivity. Advanced terminals aim to optimize the crane density and productivity to minimize vessel stay time without creating inefficiencies in other terminal subsystems.

Furthermore, equipment availability and reliability are often overlooked but critical factors. Even short equipment outages can significantly impact berth productivity if they occur during peak operations. Robust maintenance programs and equipment redundancy strategies are essential for maintaining consistent performance levels.

How does technology and automation improve berth capacity utilization?

Technology and automation offer significant opportunities to enhance berth capacity utilization without necessarily expanding physical infrastructure:

| Technology Solution | Benefit to Berth Capacity |

| Terminal Operating Systems (TOS) | Optimizes resource allocation and coordinates activities across the terminal |

| Berth planning algorithms | Maximizes quay utilization by optimizing berthing positions and handling sequences |

| Equipment automation | Delivers more consistent performance levels than manual operations, and allows tighter berth scheduling |

| Digital twin modeling | Tests different operational strategies before implementation |

| Systems integration | Ensures synchronized container flows across terminal operations |

Key takeaways: Optimizing your terminal’s berth capacity

- Conduct a thorough capacity analysis that models interactions between vessels, equipment, and terminal resources

- Develop a robust master plan that accounts for future growth and changing vessel characteristics

- Focus on operational excellence through continuous improvement initiatives targeting key performance indicators

- Invest strategically in technology and automation solutions that address specific bottlenecks

- Regularly review performance and adjust operational strategies as needed

Optimizing berth capacity requires a balanced approach that considers all the factors discussed above. The most successful terminals plan infrastructure that can adapt to evolving requirements without requiring complete redevelopment.

Small incremental gains in crane productivity or berth turnaround times can deliver significant capacity improvements when sustained over time.

The goal should be to create a balanced system where all components work together to maximize throughput. Terminal operations exist in a dynamic environment, and optimization is an ongoing process rather than a one-time exercise.

Terminal operators can maximize the capacity of their existing infrastructure while developing future-proof expansion strategies. Through detailed analysis and modeling, terminal performance can be enhanced with appropriate investments in berth capacity.

If you’re interested in learning more, reach out to the team of experts today.

Related Articles

- How does electrification influence terminal capacity planning?

- What operational KPIs are affected by energy transition efforts?

- How can terminals prepare for variable vessel arrival patterns?

- When should a port terminal consider hiring port logistics consulting services?

- How can battery swapping systems improve the efficiency of electric terminal trucks?