How Can Simulation Identify Bottlenecks in Port Infrastructure?

Simulation for Identifying Bottlenecks in Port Infrastructure

Simulation identifies bottlenecks in port infrastructure by creating accurate virtual replicas of terminal operations that reveal operational constraints and inefficiencies. Through detailed mathematical or object-=oriented modeling, simulation allows for analysis of complex interactions between vessels, equipment, and cargo flows—pinpointing exactly where delays occur and capacity limitations exist. This approach enables terminal operators to test potential solutions virtually before implementing costly physical changes, providing a data-driven foundation for infrastructure investments and operational improvements. As terminals face increasing pressure from larger vessels and higher throughput demands, simulation is an essential tool for maximising operational efficiency.

What is simulation-based bottleneck analysis in port infrastructure?

Simulation-based bottleneck analysis in port infrastructure is a methodology that uses virtual modeling to identify operational constraints and capacity limitations within terminal operations. At Portwise, we recreate the processes of a real-world port system using detailed object-oriented models with statistical distributions to account for uncertainty and variability in operations.

This approach allows for analysis of the sequence of events in an operational flow, including the individual interactions between elements such as equipment, operators, vessels, and cargo. By combining real-world data with expert knowledge on causal relationships, a predictive model can be created that mirrors actual terminal behaviour.

At Portwise, simulation models are specifically developed for container and bulk terminals, with different levels of detail for specific purposes:

- Long-term models – Have a longer modeling horizon to validate quay length, number of berths, and service levels for different vessel types, storage levels over time and equipment running hours.

- Detailed operational models – Have a shorter modeling horizon that mimic operations to a greater level of detail, including both the movements of containers and equipment as well as detailed representation of Terminal Operating Systems (TOS). This model shows if the terminal can handle peak workload volumes and what happens to terminal productivity under different situations.

Simulation has become standard practice for modern terminal operations because it provides quantitative insight into logistic systems with many uncertainties and dependencies without disrupting actual operations. It enables terminal operators to identify critical bottlenecks before they impact real-world performance.

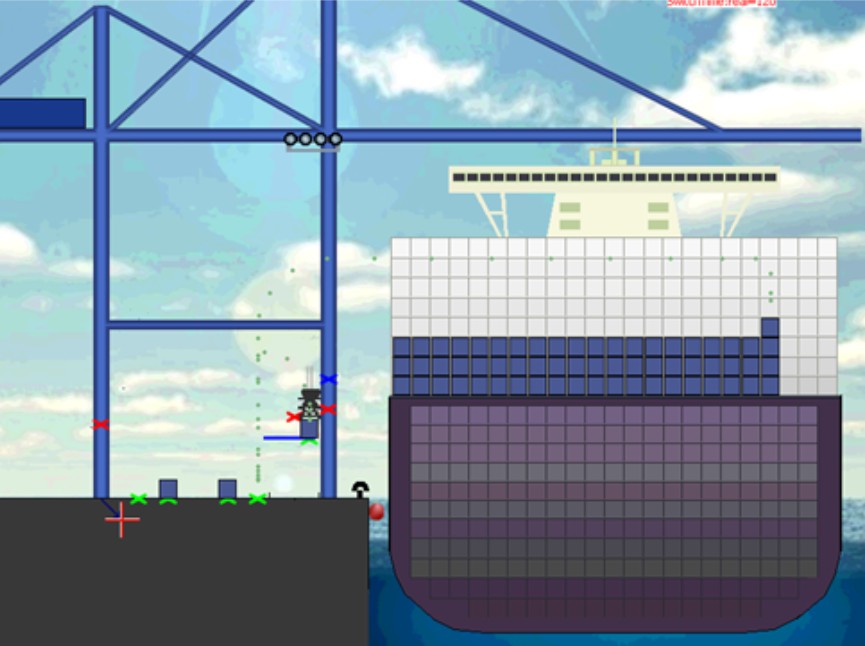

Figure 1: Example of Portwise quay crane model to analyse maximum vessel handling speed under different specs and strategies

What types of bottlenecks can simulation detect in port operations?

Simulation can detect multiple types of bottlenecks across all aspects of port operations, from waterside constraints to landside congestion points. The comprehensive nature of simulation allows for identification of both obvious and hidden operational limitations.

| Operational Area | Bottleneck Types | Impact |

| Quayside Operations | Berth capacity, crane productivity, vessel waiting times, shore power configurations | Excessive vessel waiting times, underutilized berths, inefficient vessel handling |

| Yard Area | Storage capacity limitations, handling equipment utilisation issues, transfer point congestion | Yard congestion, delayed container movements, inefficient space utilization |

| Gate Operations | Truck processing, documentation handling, gate lane capacity | Truck queuing, delayed entry/exit, landside congestion |

| Equipment Utilisation | Asset quantity imbalances, equipment allocation inefficiencies | Underutilized or overworked equipment, operational delays |

| Systems & Processes | TOS inefficiencies, work scheduling issues, maintenance planning | Cascading operational delays throughout the terminal system |

By integrating all these elements into a single model, it becomes possible to detect how bottlenecks in one area create cascading effects throughout the terminal system.

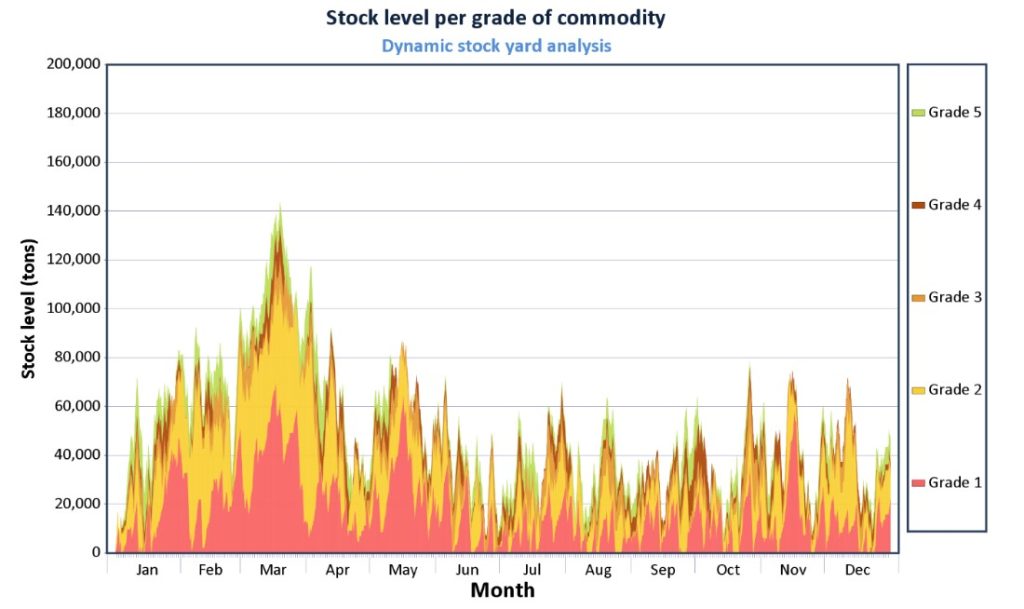

Figure 2: example output of Portwise bulk simulation showing stock levels of different product types with peak level in March

How does simulation modeling predict future bottlenecks in terminal design?

Simulation modeling predicts future bottlenecks in terminal design by creating virtual representations of planned infrastructure and operations, then testing them under various scenarios to identify potential constraints before construction begins. This predictive capability enables terminal operators to avoid costly design mistakes and implement future-proof solutions.

- Through “what-if” analyses, the potential impact of high investments can be evaluated without real-world testing. Some examples of scenarios that can be simulated include:

- Varying equipment quantities and specifications

- Testing different workload situations

- Comparing alternative layout designs (such as RTG vs ASC systems)

- Assessing automation implementations

- Evaluating electrification strategies

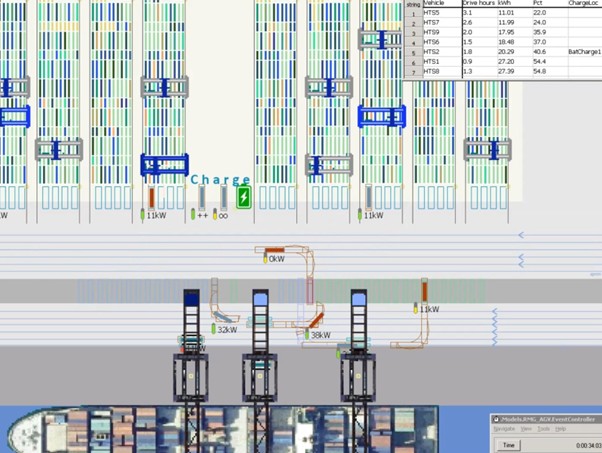

Figure 3: example of a Portwise simulation model with ASC stacking cranes, AGV vehicles and quay cranes, analysing AGV power consumption and charging requirements

The predictive power of simulation comes from its ability to stress-test designs under a wide range of conditions. For instance, terminals can be simulated with projected future cargo volumes, larger vessels, or changed commodity mixes to identify where the design might fail to deliver required performance.

A holistic, iterative, and interactive simulation approach works for both greenfield and brownfield projects. Testing for robustness, flexibility, and adaptability asks important questions like:

- What if predicted volume share of bulk commodities or of specific container types is not as expected?

- What if dwell times or TEU factor are different than expected?

- What if specific equipment performs at different behaviour than the specifications?

- How sensitive is the system against increasing workload conditions?

By identifying potential bottlenecks during the design phase, terminal operators can adjust plans before construction, potentially saving significant amounts in infrastructure costs and avoiding operational constraints that would otherwise limit future capacity.

What data inputs are needed for effective port simulation analysis?

Effective port simulation analysis requires comprehensive data inputs covering all aspects of terminal operations to create accurate and reliable models. The quality and completeness of input data directly determine the validity of simulation results and subsequent operational insights.

The essential data inputs for port simulation include:

- Vessel traffic patterns – Historical and projected vessel arrivals, vessel types and sizes, cargo volumes per call, and berth time distributions

- Equipment specifications – Technical details of all handling equipment including cycle times, speed, acceleration/deceleration profiles, weight limitations, breakdown patterns, and maintenance schedules

- Terminal layout information – Precise dimensions of quay, yard, gates, and transfer areas, along with storage capacities, road network, and potential constraints

- Operational procedures – Working hours, shift patterns, equipment assignment rules, storage allocation strategies, and priority handling protocols

- Bulk material properties – For bulk terminals, data on material handling characteristics that affect efficiency and equipment selection

Fine-tuning simulation models with historical performance data from actual operations helps ensure they accurately mirror real-world behaviour. This calibration process is beneficial for creating predictive models that terminal operators can trust for decision-making.

Portwise has developed simulation model libraries validated against data from numerous live operations, ensuring that their analyses provide reliable insights even when some specific input data may be incomplete, or when the model cannot be validated against an existing terminal

What are the key benefits of using simulation to identify port bottlenecks?

The key benefits of using simulation to identify port bottlenecks include risk reduction, optimised investment decisions, and improved operational performance through data-driven insights. Simulation delivers tangible advantages that directly impact a terminal’s bottom line and long-term viability.

| Benefit | Description | Business Impact |

| Risk Reduction | Test operational changes and infrastructure investments virtually before implementation | Prevents costly mistakes and ensures expected performance improvements |

| Optimised Investments | Quantify impact of different options to determine precise equipment and infrastructure needs | Avoids overbuilding while ensuring operational requirements are met |

| Increased Throughput | Identify and eliminate constraints that limit performance | Higher capacity without major capital expenditure |

| Improved Resource Allocation | Understand exactly where and when resources are needed | Reduced operational costs while maintaining service levels |

| Enhanced Planning | Gain deeper insights into operations for better decision-making | Stronger foundation for master planning and expansion projects |

| Future-proofing | Test terminal designs under various scenarios | Ensures adaptability to changing market conditions and regulations |

Comprehensive simulation services include detailed simulation modelling that addresses all these critical aspects of port operations, helping terminals identify and eliminate bottlenecks before they impact performance.

Take the guesswork out of your container terminal with our simulation services

Let’s explore how simulation and strategic consulting can help you invest with confidence and build a more resilient, data-driven terminal. reach out

Related Articles

- How do sensor networks enable real-time equipment tracking in automated terminals?

- What is the impact of automation on labor management in terminals?

- How do transhipment ratios influence container yard design?

- How does yard crane productivity influence terminal layout?

- Why is peak volume forecasting important in terminal planning?