Minimising surprises at go-live: the power of integrated simulation and emulation

Introduction: bridging the gap between design and operation

The automation of container terminals is transforming global logistics, offering substantial improvements in throughput, safety, and operational efficiency. Yet the journey from initial concept to live deployment is rarely straightforward. Despite meticulous planning, terminals often encounter unforeseen challenges at go-live. Software may behave unpredictably, equipment responses can diverge from expectations, and operational assumptions may not fully align with reality. These surprises can cause delays, erode stakeholder confidence, and impact the return on investment.

This article explores how an integrated approach, using the same model for both simulation and emulation, can minimise these risks throughout the terminal lifecycle. By maintaining model continuity from design through implementation and into ongoing optimisation, terminals can validate assumptions, test processes, and debug software under realistic conditions well before operations commence or gut-feeling business-logic decisions are made.

Readers will gain insight into how combining simulation and emulation not only reduces risk at go-live but also establishes a shared understanding of performance among stakeholders, vendors, and clients. The paper also highlights why the best emulation results are achieved when the process is managed by experts with both operational and emulation-specific knowledge, including awareness of the method’s limitations.

Portwise uses the following definitions of simulation and emulation:

- Simulation: a model representing port operations on a timescale of one or more shifts. It includes models of software systems (TOS, ECS, FMS, etc.), equipment (cranes and transport vehicles), containers (in transit, in storage, in vessels, etc.), and the terminal layout.

- Emulation: a model in which one or more components of the simulation model are replaced by the real system (e.g. the TOS) or real equipment (e.g. automated stacking cranes).

Simulation-driven design: establishing benchmarks and guiding implementation

A high-performance terminal operation begins with a comprehensive, iterative, simulation-driven design process. Through simulation, container terminals can proactively set performance benchmarks, validate key processes, and explore a wide range of operational scenarios. Simulation serves as a powerful enabler, providing data-driven insights that inform strategic decisions about terminal layout, equipment placement, and traffic flows. This approach not only optimisation for current needs but also ensures the flexibility necessary for future growth and scalability.

Figure 1: Simulation of autonomous trucks with double-trolley quay cranes

Simulation should not be viewed as a mere approximation but as an essential tool for identifying best practices, stress-testing assumptions, and revealing potential bottlenecks early in the design phase. By defining relevant scenarios, performance targets, and operational criteria, simulation enables terminals to:

- Establish clear benchmarks for throughput, safety, and performance

- Test and refine operational processes before implementation

- Evaluate the impact of equipment choices and layout alternatives

- Identify and mitigate potential risks or weaknesses in a controlled environment

Simulation is not about predicting a single outcome; it is about equipping project teams with robust, actionable insights that de-risk subsequent phases of automation. When used effectively, simulation creates a shared foundation for all stakeholders and vendors, aligning expectations and enabling a smoother transition to emulation, testing, and live operations.

From design to implementation: the role of early and structured software testing

As implementation begins, early and rigorous software testing becomes essential to project success. Delaying or underestimating the importance of testing can lead to critical issues during go-live. Testing must therefore be approached as an iterative process initiated as early as possible in the project lifecycle.

Performance and integration testing are critical components of the software implementation process, and emulation serves as the primary tool for conducting such testing. Emulation involves creating a virtual representation of the terminal’s operating environment, connecting real terminal systems to a simulated model of the physical terminal. This allows for comprehensive testing of system behaviour, interfaces, and workflows under realistic conditions—without the risks or costs associated with live operations.

Using the same model for both simulation and emulation allows teams to compare results in truly like-for-like scenarios. This makes it easier to identify deviations from expected outcomes and address performance gaps early in the Ultimately, emulation provides a safe, controlled, and repeatable environment for both performance validation and integration testing, supporting a smoother transition from design to live operation.process.

Key advantages of emulation include:

- Reliable software validation: provides an accurate, controlled, and repeatable platform for verifying complex systems before deployment

- Algorithm optimisation: allows tuning of planning and control algorithms ahead of go-live

- Operator and engineer training: offers realistic, hands-on training well before equipment is introduced

Integrating simulation and emulation throughout the implementation phase bridges the gap between design and live operation, reducing risk, validating assumptions, and preparing all stakeholders for successful, high-performance automation.

Start simple, grow smart, and go live prepared

A phased approach to implementing an automated container terminal is essential for minimising risks during go-live. Starting with smaller, controlled operations allows teams to refine and improve processes before scaling up. This principle applies not only to physical terminal operations but also to laboratory or pre-live testing environments. For example, beginning with a simple flow, such as 40’ container discharge, can help determine whether the systems function and interact as intended.

This incremental approach can also be applied when testing standalone software components—such as an FMS or ECS—connected to a simulation model. This method is far more comprehensive than traditional testing, which typically relies on scripts executed in isolated environments and focuses on specific operations or equipment. Simulation-based emulation tests the full operation and the interactions between the different related software components, and can be used with modules from different suppliers. Because only one component is swapped from the simulated environment to the real system, comparing performance indicators between the two is straightforward.

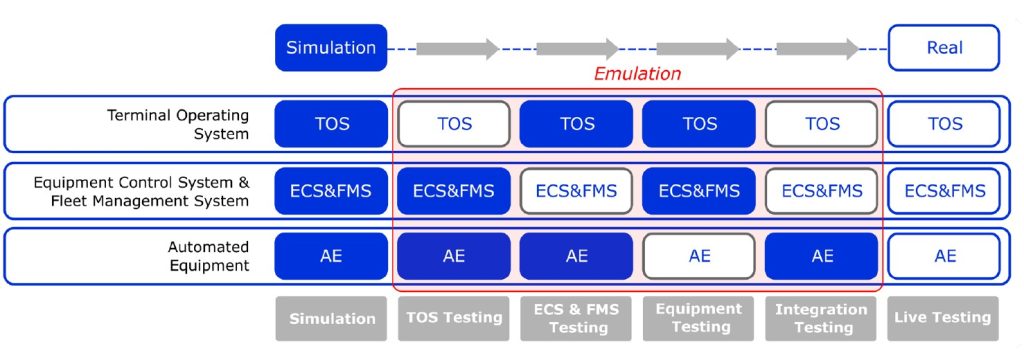

Figure 2: Simulation to emulation, showing individual components that can be exchanged for functional or performance testing

What follows is the testing of multiple software components. This approach makes it possible to test the quality of the terminal systems together. Although errors may be harder to identify due to scenario complexity, this approach provides greater insight into system performance. An important added value of this emulation approach is that, next to executing a comprehensive test and finding bugs, the container terminal obtains key performance indicators, such as vessel productivity or waiting times. Figure 2 shows a visual representation of some of the combinations that are possible for a (semi-)automated terminal that has 4 software systems – TOS, Scheduler, ECS and FMS.

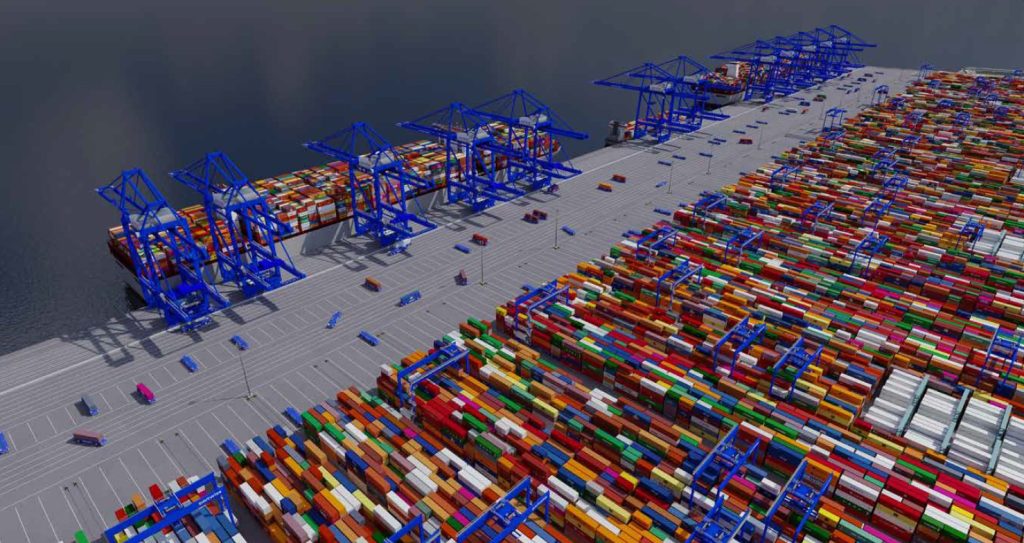

Figure 3: 3D representation of a model used throughout the lifecycle of container terminal operation: Simulation – Functional testing – Performance testing – Optimisation

Having this setup available pre-go-live allows teams to test new features, uncover missing functionality, resolve bugs, and fine-tune software parameters—all of which contribute to a more stable and reliable go-live.

Pitfalls in emulation deployment

Experience across several implementation projects has highlighted common pitfalls. Non-experts often struggle to master emulation tools due to challenges such as inconsistent data, overly rigid simulation behaviour, expectations for manual inputs in operational systems, lack of hands-on experience, and limited understanding of emulation logic.

In practice, emulation is mostly used during the project phase of a semi- or fully automated terminal implementation, with a strong focus on functional and performance testing. Its continued use after go-live—for ongoing testing, algorithm tuning, or operator training—is far less common.

To truly unlock the value of emulation, expertise is more important than the tool itself. Emulation becomes most effective when managed by teams that combine deep operational knowledge with technical experience. When used in this way, emulation becomes a powerful support mechanism for terminals aiming to achieve high-performance automation and reduce the risks associated with go-live or software upgrades.

Summary: the power of integrated simulation and emulation

Automation is reshaping the future of container terminals, offering significant benefits in throughput, safety, and labour efficiency. However, the journey from manual to automated operations is complex and fraught with challenges.

Success depends on a structured, phased approach that integrates simulation and emulation across the terminal lifecycle. By designing for performance, testing seriously, and committing to continuous improvement, terminals can overcome integration hurdles and achieve operational excellence.

Using the same model for simulation and emulation acts as a powerful bridge between design and reality. It enables container terminals to test, validate, and optimise systems before live deployment, reducing risk and enhancing reliability.

Finally, the complex landscape of systems at (semi-)automated terminals and the many factors (e.g. data inconsistency) that make or break an emulation model means that emulation is not straightforward for non-experts.

Interested in discussing how an integrated simulation and emulation can minimising surprises at go-live in your container terminal?

About the authors

Kaj de Groot works as Director of Automation Projects at Portwise. He has worked in the ports and terminals field for about 11 years and has been involved in many different brownfield and greenfield container terminal automation implementation projects across the globe.

Dr Yvo Saanen works as Managing Director at Portwise. As founder of TBA and Portwise, he has worked in logistics optimisation for more than 25 years. He holds a PhD in the design of automated terminals. He lectures about simulation, emulation and optimisation at various universities.

Melvin van Henten works as a Senior Automation Consultant specialising in port operations and automation. He has supported implementations, go-lives and operations focusing on process optimisation, equipment control, and performance improvements across semi- and fully automated terminals.