Bringing autonomy to daily container terminal operations: from promise to practice

Autonomy from promise to practice: are we fully ready?

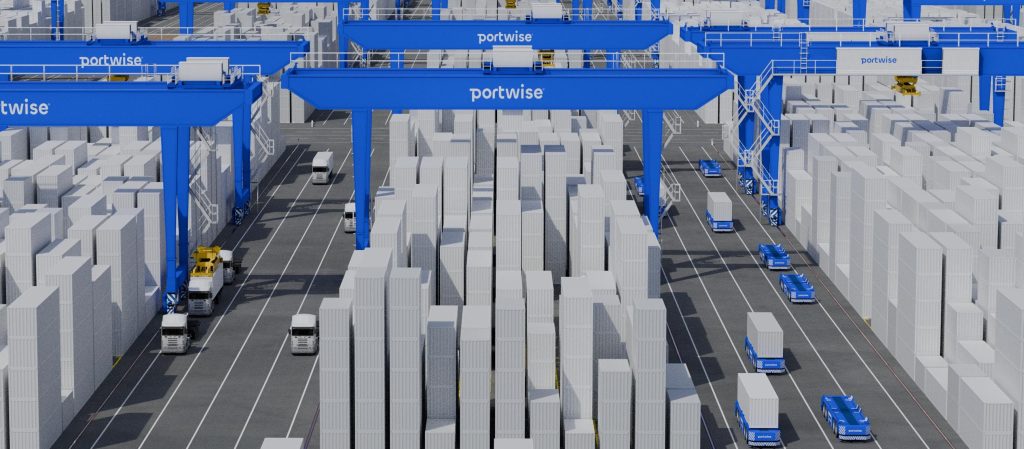

Autonomous vehicles (AVs, e.g., Figure 1) offer exciting potential for terminal logistics. They are expected to transform the industry with their flexibility and potential for operational efficiency, workforce evolution, and cost optimisation. Although not yet fully applied in day-to-day full-scale operations, sensible use cases are already foreseen with most short- to medium-term feasibility and business viability (see Portwise publication “Autonomous vehicles – the holy grail?” in PTI Journal Edition 140). Tremendous progress has been achieved with technological developments, site proof-of-concept pilots, as well as terminal (partial) adoptions.

Yet, the question remains: are we fully ready for autonomous vehicles in practice? Success depends on far more than simply navigating from A to B. In complex port environments, these systems must operate safely and efficiently alongside other equipment, under real-world constraints, in diverse operational contexts (e.g., severe weather conditions) and within the dynamics of a container terminal. Gaps still exist before AVs are fully ready for live operation. Challenges and hurdles are faced at different levels.

To address these, at Portwise we believe that advanced modelling via simulation and emulation can play a highly beneficial role. In the remainder of the article, we will present our perspective on the importance of such a role, drawing on our experiences and lessons learnt, as well as insights and feedback from many solution providers, industry peers, ports, and terminals.

Figure 1: Cases with autonomous intelligent guided vehicles (IGVs) in a non-mixed traffic operation environment with perpendicular ASC yard (left) and autonomous terminal trucks in an intermodal site (right).

Key challenges and hurdles – a selection:

- Technical challenges: Precision and accuracy are not the only requirements. The checklist also includes localisation (in dense port environments), reliability (in various weather conditions), redundancy (in case of breakdowns), and interoperability (with legacy systems) for vehicle mapping, sensor fusions, and navigation.

- Regulatory concerns: Regulations and standards are required to ensure no safety compromise for AVs operating in human-accessible environments. Although standards such as the EU Machinery Directive (2006/42/EC) exist, there is still arguably no unified regulatory framework for AVs in ports. International differences create uncertainties and ambiguities around compliance, certification, operational boundaries, liability, and insurance.

- Operational complexity: Container terminals are highly dynamic and subject to changing vessel schedules, yard configurations, and cargo flows. Advance planning is not feasible, as it requires robust safety protocols, fail-safe mechanisms, and real-time adaptability for AV implementation.

- Performance challenges: To ensure AVs can safely and efficiently drive from A to B does not guarantee performance. It is a balancing act of job dispatching, equipment assignment, routing planning, traffic distribution, congestion mitigation, deadlock avoidance, priority ruling, and sequence management. It is about managing an entire fleet, not just a handful of vehicles; about handling exceptions, not just “happy day” flows; and about managing interactions with manned vehicles, quay cranes, yard cranes, and human workers. Questions remain as to whether full autonomy will be able to address all use cases or whether a centralised fleet management system will still be required.

Addressing the challenges and the role of advanced modelling before proof-in-operation

Achieving full readiness for day-to-day autonomy requires addressing these challenges and solutions at different levels, too. Greater collaboration between various stakeholders (ports and terminals, technology providers, and governments) is what is needed to develop more harmonised policies and standards for AV certification, operation, and data governance. Rapid developments and increasing trials and pilot programmes continue to improve the fundamental technical functionalities of AVs towards full implementation. From an operational and logistical standpoint, however, the industry does require more insights and experiences. These aspects remain the most complex within the entire puzzle, given the highly dynamic operational conditions within terminals and the need for tailored solutions. Here, advanced modelling approaches become essential. They are cost-effective and beneficial for:

- Risk-free testing and improvement of AV behaviours and logic under various operational scenarios and dynamic environments (layout changes, peak and average conditions, adverse weather, equipment failure, interaction dynamics, etc.) without the need for real facilities disruption of live operations.

- Operation and performance evaluation of AVs in simulation benchmarking manual operations to assess efficiency, safety, and cost-effectiveness.

- Robustness and scalability planning of how AV fleets will perform as terminal volumes grow, fleet size increases, and the interactions with manual traffic intensify.

- Phased integration and implementation with simulation and emulation tools to enable stepwise testing of real hardware and software system components – not just for functionality but also for performance of individual system components.

- Visualisation and observations of behaviours and operation of AV in driving, routing, interactions with other equipment, manned vehicles, etc., for validation and demonstration.

Figure 2: Modelling of autonomous terminal trucks mixing with road trucks in RTG yard (example of a 3D visualisation)

Key elements for AV modelling

Simulation and emulation have proven their benefits to support successful development and implementation of technologies within our industry in the past (e.g., TOS, ECS, automated guided vehicles). The same concept and principles can be well replicated in a similar fashion to support the industry’s adoption of AVs.

However, there are many nuances within the concept of simulation and emulation. To reap the benefits, it is critical to have the right AV modelling in simulation and emulation, in terms of the modelling scope, the level of details, and the setups and external factors to be built within the model. Simply put, garbage in is garbage out, and simulation/emulation is not just for the sake of modelling and animations. Past lessons are therefore still applicable; yet new features of AVs require additional attention:

- Clear level definition for modelling: The purpose of modelling should always be clarified. Emulation, intended as linking simulated/emulated system components with the real counterparts, may be a clearer concept; simulation can often be ambiguous. Depending on the purpose, simulation could range from AV vehicle motions, sensor simulation (camera/lidar/radar), AV navigations and routings, as well as a full-fledged terminal operation and performance simulation with AVs and other equipment. These consequently lead to different considerations of the simulation approach and tooling.

- Scope and elements in modelling: Even with clearly defined simulation levels, the question of what elements are relevant to include (or not) matters. This refers to both internal and external elements. For motion simulations, the scope may be limited to the AV vehicle and hardware. For sensor, navigation and routing, terminal layout, infrastructure, obstacles, environment, and weather conditions become relevant. A full terminal operation and performance simulation requires additional external elements such as the terminal’s operation conditions, cargo workflows, full-scale interactions between all terminal equipment and external traffic, and the logic of the TOS and EMS for job planning. order assignment, etc.

- Continuous validation in modelling: Model validation is essential to ensure the reliability of modelling outcomes for decision-making. While many modelling components have been validated against real data, real benchmarks and empirical data remain scarce for the validation of AV modelling. Continuous validation will be necessary for realistic, state-of-the-art AV modelling over the long term.

- Level of autonomy in modelling: Unlike conventional AGVs, AVs are designed to navigate autonomously using sensors, whereas AGVs are centrally orchestrated by ECS for AGVs’ routings. This naturally requires different vehicle modelling approaches. However, debate remains as to whether full autonomy of AVs is sufficient, or a central software layer would be beneficial for efficient management of container loading and vehicle sequence, route planning and priorities, transfer points, handshakes between different equipment, etc. A clear definition of the autonomy level becomes, therefore, a prerequisite before AV modelling.

Figure 3: Modelling of interchange between IGVs and road trucks with a cantilever RMG yard (example of a 3D visualisation)

Insights from recent Portwise’s autonomous vehicles modelling

Through modelling and studying various AV concepts using simulation tools, Portwise has gathered valuable insights, including:

- The importance of having a centralised software layer to define routes, manage sequencing, and support container handover processes to facilitate higher efficiency and performance, especially for large fleet operations.

- The need for a unified traffic rule set for both AV and manned traffic within the terminal, and a need for clear crossing priorities, to achieve more safety and more efficiency in interactions, as compared to a free flow or first-come, first-served setup at junctions.

- Different driving directions within the terminal could lead to a trade-off between driving distance and traffic crossings. For example, a one-way traffic setup between waterside and yard with fewer crossings results in less vehicle hindrance, smoother overall traffic flow, and higher performance, even if the setup causes longer vehicle driving distances.

- The value of configuring both no-stop areas to disallow conflicts at critical points and waiting positions to allow for independent AV waiting and buffering, within AV route segments.

- The benefits of limiting interactions between AVs and other vehicles as much as possible via layout configurations in the first place (e.g. dedicated zones and lanes, yard interchange separations, etc.), to minimise congestion and dead-lock sensitive situations.

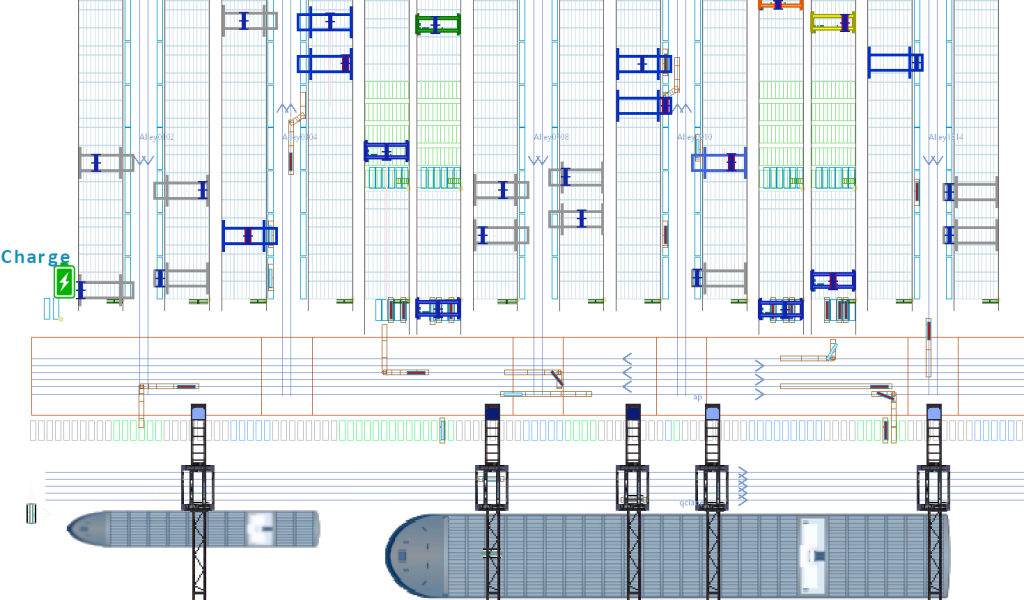

Figure 4: Modelling of autonomous IGVs in a perpendicular Cantilever RMG yard (example of a 2D visualisation)

Concluding remarks

AVs have the potential to transform container terminal operations. However, many unknowns remain – both in virtual labs (via modelling) and in reality (via trials and pilots) – for AVs’ full readiness. We believe advanced modelling via simulation and emulation will play a key role in this journey. Yet, to reap the benefits to support development and implementation, it is a prerequisite to have the right AV modelling approach.

By sharing Portwise’s experiences and lessons learnt, this article summarises what we believe are the essentials for effective AV modelling.

Interested in discussing autonomy in container terminals?

About the authors:

Dr. Zack Lu works as a Senior Project Manager at Portwise. In the last decade, he has worked in various terminal projects related to design, simulations, operation optimisation, automations, etc.

Kaj de Groot works as Director of Automation Projects at Portwise. He has worked in the ports and terminals field for about a decade and has been involved in many different terminal design and automation implementation projects.

Melvin van Henten works as a Senior Automation Consultant specializing in port operations and automation. He has supported implementations, go-lives and operation focusing on process optimization, equipment control, and performance improvements across semi- and fully automated terminals.

This article has been published in PTI Journal Edition 154.