Portwise’s research to efficient autonomous driving: what have we learned so far?

A large gap exists between current possibilities and future requirements of autonomous driving on (container) terminals. While autonomous driving has big potential, the industry has little experience with how to implement this efficiently in full scale operations and mixing with manned trucks. Portwise contributes to innovative research to deploy large fleets of Autonomous Vehicles (AVs) in busy operations by developing layouts and logic to make this work. The layouts and logic are tested with Portwise’s simulation models for container terminals, which are the most advanced and accurate simulation models in the world for these terminals. This article describes interesting findings of Portwise’s research work of the last 2 years.

Additional information on this topic can be read in these articles: Bring autonomy to daily container terminal operation: the role of advanced modelling and Autonomous vehicles: the way forward for automation?

Introducing Portwise’s innovation background

Portwise uses its design expertise and simulation models, operational data, and tooling to improve terminal design, operational efficiencies, capacity planning, and automation strategies. One direction in which terminal operations can be improved is via innovative container handling solutions.

Portwise is always eager to investigate how innovative solutions can be deployed in specific terminals:

- Which operating strategies or rules are needed to make efficient use of a new concept?

- Under which conditions does it work, and how does the concept impact terminal productivity?

These questions can often be answered by using our detailed and accurate simulation models, in which these innovative concepts are implemented by our simulation experts.

Portwise has been studying many innovative solutions in the past. Examples include Lift-AGVs, automated straddles, highbay storage solutions, alternative quay crane designs, alternative horizontal transport systems, and twin-carry RMGs. This article focuses on recent autonomous driving research done by Portwise with its simulation tools.

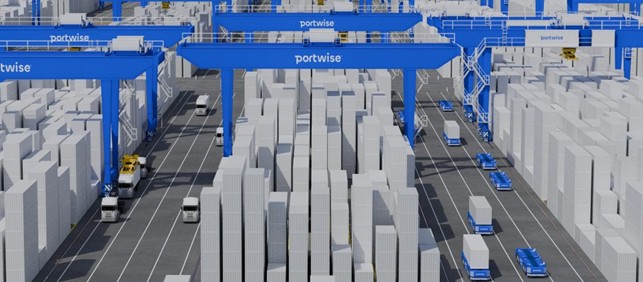

Large fleets of autonomous vehicles are driving in our simulation models

Autonomous Vehicles (AVs) offer exciting potential for terminal logistics. They are expected to transform the industry with their flexibility and potential for operational efficiency, workforce evolution, and cost optimisation.

Various suppliers offer autonomous driving solutions. AVs can drive routes accurately, detect obstacles and other vehicles, and respond to those by braking or rerouting. This works in small and relatively simple environments. The intention is to deploy large AV fleets in terminals where challenges will occur that are unsolved yet by the suppliers, such as:

- Large scale mixing between AVs and manned trucks

- Driving in heavy congestion in layouts with many crossings

- Sequencing of AVs to arrive in proper order at quay cranes or other locations

Although autonomous driving is not yet fully applied in day-to-day full-scale operations, Portwise already has large fleets of autonomous vehicles driving efficiently in its simulation models.

In cooperation with different terminal operators and different AV suppliers, a variety of layout options, driving strategies, conflict responses and other behaviours have been designed and tested in a simulation lab.

This article summarises some of the many interesting findings of Portwise’s recent research activities.

Fundamentals of autonomous driving

Before going to the details, it is important to reflect on the fundamentals of autonomous driving that Portwise determined for the purpose of deployment in (container) terminals. These fundamentals are special rules or concepts of which Portwise believes these should be applied to allow safe and efficient use of autonomous vehicles in mixed or dense traffic operations on terminals.

Portwise defined the following fundamentals:

- All vehicles on the terminal must know and be able to easily understand the traffic rules. AVs know and respect the rules when interacting with each other. In case of mixed traffic, it is equally important that human drivers of trucks (or other moving equipment) understand and recognise traffic situations and know how to deal with other trucks and with AVs in different situations. This fundamental makes the operation safer and allows faster decision making and action by AVs.

- Traffic rules apply to all vehicles:

- Both AVs and manned trucks comply with the defined traffic rules.

- Rules are clear to both AVs and manned trucks, e.g. visualised by traffic lights, stop signs, no-stop-markings.

- AVs are aware that AV-specific-rules that apply to them also apply to all other AVs. This fundamental allows AVs to ‘trust’ that other AVs will execute a specific behaviour in specific conflict situations.

- AVs signal to manned trucks what they are doing and what they are going to do, e.g. indicate in which direction they intend to move, or indicate when they give way to a truck. This AV behaviour creates trust for drivers to safely manoeuvre between the AVs and speeds up traffic flow.

- Limit interactions between AVs and other vehicles as much as possible to minimise congestion and dead-lock situations in by designing smart layout and routing decisions.

- A central software system (ECS ‘equipment control system’ or FMS ‘fleet management system’, or a combination of both) should support the AV operations with:

- Defining routes and sending route instructions to AVs. This helps routing AV over less congested roads or avoiding complex crossing situations.

- Supporting container handover processes (interchange) to/from quay cranes, rail cranes, and yard cranes, including sequencing and assigning hand-over positions.

Example of road truck handling on one side of stack and AV handling on the other side; the vehicles drive separately here, but also encounter each other on other roads where separation is not possible.

How to deploy autonomous vehicles in a terminal environment – findings from simulation studies

This paragraph contains two sections. The first elaborates on research of generic traffic of AVs. How can AVs drive safely and efficiently on a terminal, all or not in mixed traffic operations. The second part focuses specifically on research of AVs in RTG terminals, one of the most complex terminal operations to use AVs in, yet likely the terminals with most potential to benefit from AV deployment.

Traffic insights

AVs are well capable of precise manoeuvring in all kinds of directions, especially in low-traffic environments. When the roads become more congested and contain crossings with other roads, AVs are at risk of getting stuck, slowing down or waiting long times to merge onto roads or to pass crossings, more than manned trucks experience. We observed in our models, and in real-life testing environments, that AVs can spend tens of seconds up to minutes at junctions, until they decide it is safe enough to drive, even at crossings that are not that busy. To help AVs navigate faster and safer through a terminal, Portwise has investigated several measures in layout design, routing and driving behaviour which reduce congestion and delays:

- Priority: Portwise designed a set of rules that help vehicles recognise better which vehicle gets priority under which conditions. The rule set includes various types of priority:

Priority roads: define which roads have priority over other roads. Both AVs and trucks can recognise this, for instance by markings on the pavement or stop signs and give way to each other when needed. - Go=go priority: as soon as vehicles have started a special action, such as turning, driving backwards, or passing a crossing, they get priority to finish this action. Other vehicles need to stay out of the way when they recognise other vehicles making such moves. For AVs this behaviour can be implemented in their logic, manned drivers may need instructions, although this behaviour is not that different from logical driving on the streets with respect for other drivers.

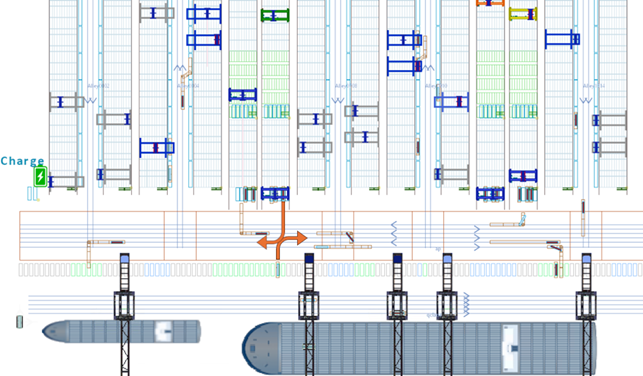

- Location specific priorities: each container terminal has unique features that may require specific priority solutions that the default solutions do not cover. One example applies to terminals with a perpendicular ASC yard layout, like the picture below. At the red arrows, one vehicle driving from quay to yard need to merge in opposite direction onto the highway lanes as another vehicle driving from yard to quay. This opposite merging behaviour is deadlock-sensitive without special priority rules. Without such rule, both AVs might drive so close towards each other that neither is able to make a turn onto the apron eventually.

Example of a generic Portwise simulation model where AVs from quay and from yard both merge on the central apron or highway lanes from different directions.

- Congestion reduction – deploy layout design measures to minimise the number of conflicts that vehicles encounter while driving:

- AVs have more difficulty driving through busy crossings than human drivers when vehicles approach crossings from 4 different directions and leave in 4 different directions. Routing strategies were analysed where crossings had 3 directions for incoming traffic and/or 3 directions for outgoing traffic. This logic provides good mitigation against queuing / congestion, sometimes at the expense of small detours.

- Traffic light implementation for busy crossings between road trucks and autonomous vehicles:

- At very busy crossings where incoming and outgoing traffic in 4 directions is inevitable, implementation of a smart traffic light system makes it possible to have hundreds of vehicle passages per hour through these crossings. A smart traffic light should for instance apply dynamic times for green and red and may require specific schemes that define or detect which directions can have a green light simultaneously. Traffic lights are of course also useful for busy crossings between only manned vehicles, and AVs benefit from this too.

- Reduce traffic on busiest highway lanes by smart rerouting:

- Certain roads in terminals tend to become more congested than other roads. A router for AVs can plan routes in a smart way to reduce congestion on busy roads by planning specific routes over other roads. In certain designs, it is beneficial to create additional roads for the purpose of rerouting AVs over less busy roads.

- Different QC buffer management (origin and destination dependent):

- If there is sufficient space at the apron, terminal layouts with AVs can use buffer positions near the quay cranes for AVs to wait without hindering other AVs. AVs may wait here when they have no new destination yet or when they have no clearance to proceed to their next destination (e.g. to a quay crane with an out-of-sequence container). Routes to and from these buffers often conflict with each other. Portwise designed a buffer-selection strategy that reduces conflict routes between AVs when driving to or from the buffers. This logic reduced delay time in the buffers significantly in busy areas in the simulation model.

RTG layout insights

Implementing fleets of AVs in RTG terminals provides additional challenges over other layouts:

- Driving and queuing space is quite scarce.

- Many interactions between AVs and manned trucks are possible.

- RTG legs need to be avoided when shifting an AV between interchange/handover lane and driving lane alongside the RTG blocks.

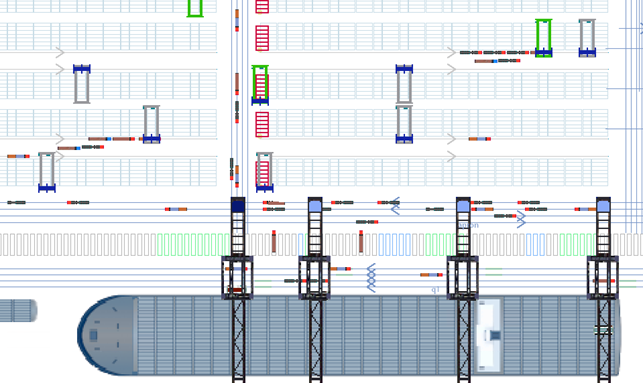

Example of a generic RTG terminal in a Portwise simulation model, used for testing different AV layout and routing options.

More research regarding this topic is ongoing within Portwise. So far, we observed the following findings:

- To prevent queuing of AVs up to the entry of the RTG blocks or on the travelling lanes alongside the block, active control of the number and position of AVs travelling to RTG blocks can be implemented. A central decision tool should judge whether it is possible to send more AVs to specific positions alongside the block. This tool must also consider (manned) trucks that are travelling to or present at the RTG blocks.

- Logic is necessary to move AVs away from RTG blocks when they do not receive a next destination from the terminal operating system (e.g. when no new job is assigned to them). This logic prevents AVs from blocking other AVs and trucks that need to be at the same RTG block.

- Direct entry into RTG interchange lane is easier to implement with AVs than merging from the driving lanes. Depending on the level of technology of AV development, it can be a better solution to route AVs directly onto an interchange lane at the start of the RTG block, rather than merging from the travel lane onto the interchange lane at the correct position. The conflict between RTG and AV can then be prevented. This comes at the expense of flexibility and performance. The simulation model can be used to judge the impact.

- In current practice, RTGs often start collecting a load box from an RTG block when the RTG driver recognises which truck or terminal tractor is approaching. With AVs, this is a risky decision, since they are less likely to solve potential traffic issues than manual driver can solve. The AV might not be able to reach the target position due to conflicts it detects. An RTG would then carry a box for which the corresponding vehicle will not reach the interchange position. To prevent this, RTGs should only start executing jobs for AVs, if the arrival of the corresponding AVs is guaranteed.

- A couple of other situations that are observed in simulations still need to be resolved efficiently:

- AVs that have finished handling at RTG block and should leave can get stuck behind other AVs or road trucks that are waiting at close distance in front of them on the interchange lane, or at the side on the driving lane. AVs do not have enough space to move out. They must wait until the blocking vehicle moves away. This can also happen with manual drivers, although people can find more creative ways to leave with their truck from a ‘stuck’ situation, especially in coordination with other drivers.

- AVs are often waiting in queues in RTG layouts because there are many interactions with other AVs, with trucks and with RTGs possible. There are cases where AVs may drive too far as they can go, until coming to a stop for a queue. They may stop in positions that block too much other traffic or RTGs, even possibly resulting in deadlocks. For instance, an AV that gets stuck while crossing the RTG-wheel-lane can block the entire terminal operations. Smart queuing behaviour for AVs in RTG terminals is yet to be designed.

Further research and implementation of AVs in terminals

Portwise remains active in researching further potential, complications and solutions in implementing autonomous driving in container terminals.

In different layouts where AVs were researched by Portwise, each container handling concept and layout showed different types of complications during testing the AV fleet in a simulated environment. The selection of described solutions works for some of them, needs tweaking for others and may not work in different terminals. Portwise’s simulation models help investigating how well specific solutions work in specific layouts and situations. They also provide guidance on which logic should be covered by what part of the system such as TOS, ECS, FMS or on the AV itself.

Interested in discussing autonomy in container terminals?

About the author: Arjen de Waal

Arjen works as manager of the simulation department, simulation expert and product owner of the simulation library at Portwise. Arjen has been involved in many terminal design and optimisation projects all over the globe, and is in charge of the simulation department since August 2011. He is also one of the coordinators and designers of the Portwise Academy, the internal training program.

At TBA – the origin company of Portwise – Arjen was member of the R&D Board, TBA’s internal innovation program. Arjen holds an MSc in Operations Research and Management at the University of Amsterdam.