Requirements for Data-Driven Terminal Operations

In today’s digital age, data surrounds us. It drives wars, it fuels decisions, and it powers innovation. Yet, in many ports and container terminals across the globe, we’re still not fully using the data we already have. The reasons? Poor data quality, incomplete records, outdated systems, and a reliance on informal communication like phone calls and emails. It’s time for change.

Why Data Matters in Port and Terminal Operations

Ports and terminals operate in a VUCA world—volatile, uncertain, complex, and ambiguous. Trade tariffs, geopolitical tensions, and supply chain disruptions are unpredictable and impactful. To navigate this environment, terminals must make faster and smarter decisions. And for that, data is indispensable.

However, we’ve often found that while data is abundant, it’s also inconsistent and unreliable. In one case, we analyzed crane error data from a terminal: 20,000 errors, of which 12,000 were unique. No patterns. No actionable insights. The reason? No structured documentation, and no linkage between problems and resolutions. Even machine learning can’t help when the foundation—the data—is flawed.

Digital Ports Demand Data-Driven Thinking

As terminals become more automated, fleets of robotic equipment depend on real-time control by intelligent systems. But these systems rely heavily on accurate input—arrival times, load lists, equipment statuses—and right now, that input is often incorrect or incomplete.

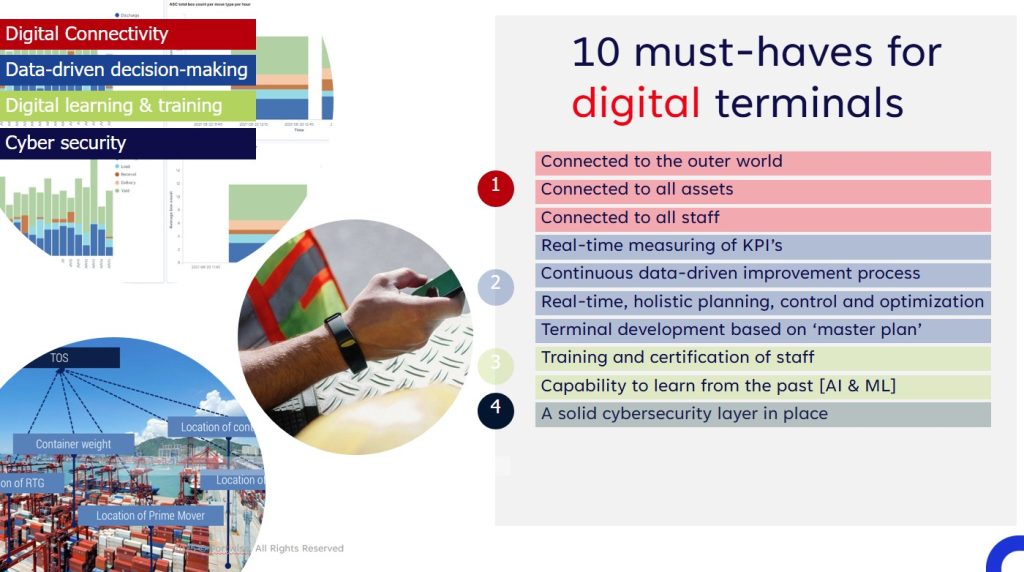

So what do future-proof, data-driven terminals need? At Portwise, we’ve identified 10 key requirements, grouped under four main pillars:

- Digital Connectivity

-

- Connected to the outer world: Eliminate faxes, emails, and phone calls. Embrace standardized digital formats with secure connections and rich metadata for priority, quality, and reliability.

-

- Connected to all assets: Real-time tracking of equipment and containers is a must. Predictive maintenance becomes possible when technical and operational statuses are known continuously.

-

- Connected to all staff: Equip personnel with real-time digital tools—RFID, tablets, smart apps—to improve safety, communication, and productivity.

-

- Real-time KPI measurement: Stop relying on manual spreadsheets. Automatically track service levels, yard occupancy, equipment use, and other performance indicators at the source.

- Data-Driven Decision-Making

-

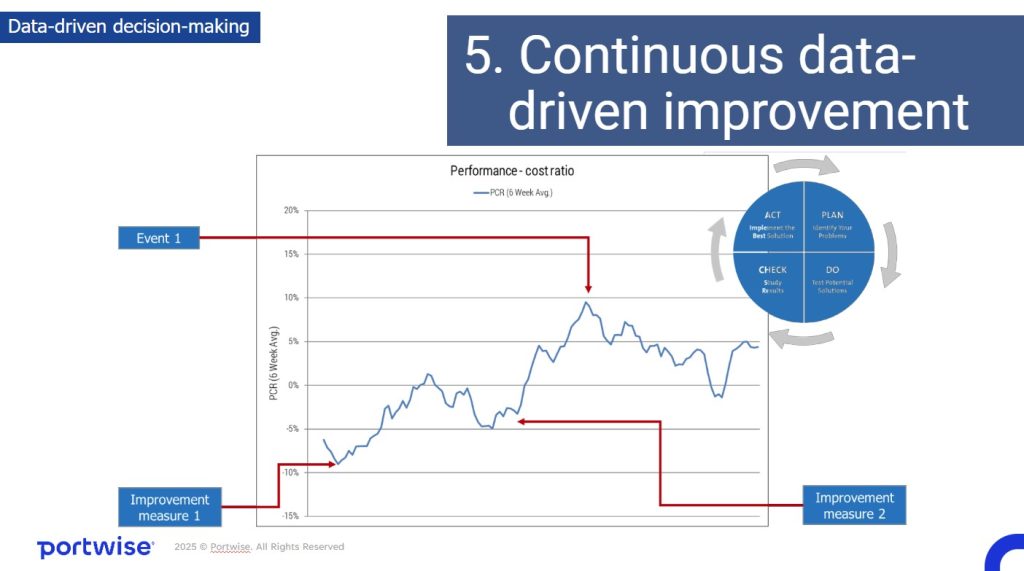

- Continuous improvement loop: Use performance data to understand what went wrong (or right), why, and how to replicate success or prevent failure. Make improvement part of the culture.

- Continuous improvement loop: Use performance data to understand what went wrong (or right), why, and how to replicate success or prevent failure. Make improvement part of the culture.

-

- Holistic, real-time optimization: From berth planning to yard operations, decisions must be dynamic, contextual, and optimized in real-time with the help of algorithms and analytics.

-

- Plan based on facts: Use historical data to make robust, flexible plans. Automate re-planning where possible. Support people with data, insight, and guidance—augmenting human intelligence.

- Digital Learning & Training

-

- Develop the terminal—and the people—digitally: Use digital twins to test layouts and workflows before building. Train staff using realistic virtual scenarios. Gamified microlearning and certification must become the norm.

-

- Learn from the past, look into the future: Operations are repetitive, which makes them perfect for pattern recognition. AI and machine learning can provide predictive insights, but only if quality data is available.

- Cyber Security

-

- Secure the foundation: Digital ports and terminals are vulnerable if not protected. Implement layered cybersecurity—firewalls, secured communications, access control, and compliance with privacy laws like GDPR. Train staff. Test systems. Protect the data.

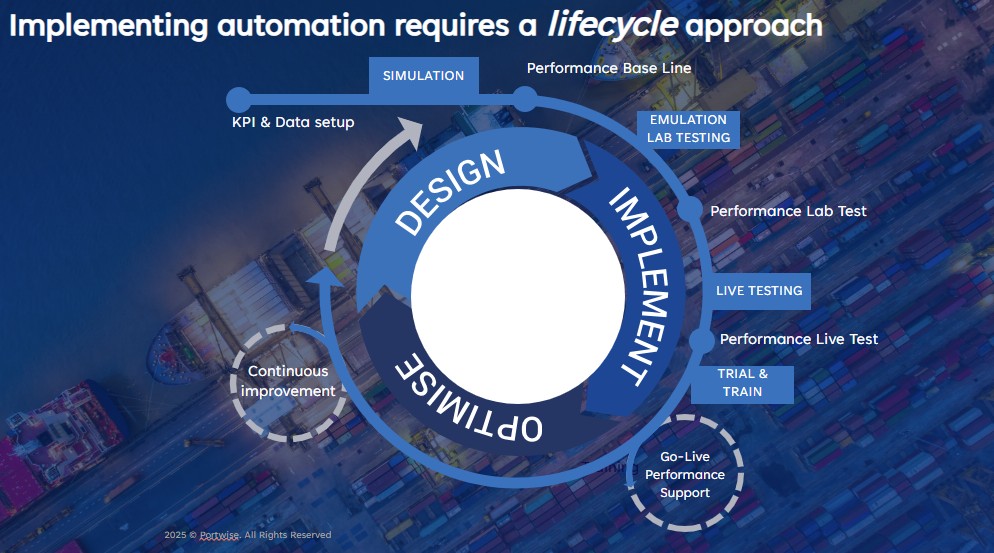

Built Into the Lifecycle

These principles should not be “bolt-ons.” They must be embedded from the start—during design, implementation, and operations. Use dynamic models to simulate, test, and validate. Mistakes on paper are cheap. Mistakes in production are not.

To make digital port and terminals operations successful, we must not only adopt technology—we must change how we think and work. This transformation starts with leadership. Data is already the fuel. Let’s build the engine that can run on it.

Take the guesswork out of terminal investments

Let’s explore how simulation and strategic consulting can help you invest with confidence and build a more resilient, data-driven terminal. Book a Free Consultation

By Dr. Yvo Saanen, Managing Director at Portwise