How do you estimate storage requirements for bulk terminals?

Understanding bulk terminal storage requirements: a critical planning component

Estimating storage needs at a bulk terminal is not just a formula—it’s about understanding how cargo moves through the system. The goal is to work out how much space is required to keep things flowing smoothly, based on throughput, cargo properties, and the peaks that come with seasonal or market shifts.

Get the estimate wrong, and the whole operation feels it. Insufficient storage means bottlenecks, waiting vessels, unhappy customers and demurrage bills piling up. Too much storage, on the other hand, ties up capital in land and infrastructure that may sit half-empty. The sweet spot is enough capacity to handle today’s volumes, with flexibility to scale for tomorrow.

Well sized yards, silos, and warehouses do more than just hold material. They also create room for blending, mixing, screening, and other value adding activities. And because storage often eats up a large share of a terminal’s footprint and budget, getting it right is one of the most important steps in cost effective design and long term performance.

What factors influence bulk terminal storage capacity requirements?

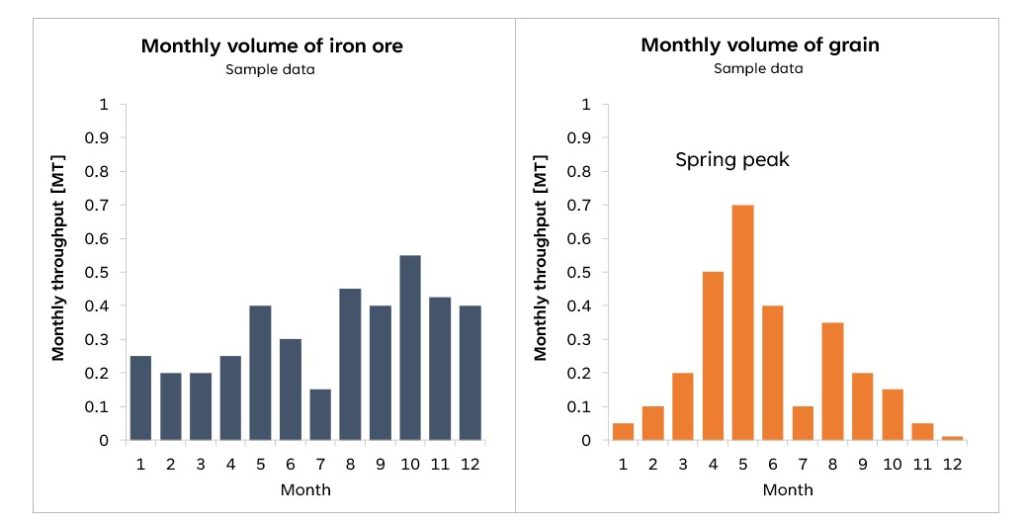

Several factors shape how much storage a bulk terminal really needs. It starts with the basics: cargo type, throughput, dwell times, and operational patterns. Commodity characteristics significantly influence storage requirements. Besides that, each commodity comes with its own quirks—grain may swing wildly with harvest cycles, while iron ore tends to rise and fall with global market. These patterns drive how storage fills and empties across the year. Also, vessel arrival patterns directly impact storage utilization, with irregular arrivals typically requiring larger storage buffers than predictable schedules.

Figure 1. Each commodity comes with its own throughput pattern

Dwell time—the period cargo remains in storage—is another critical factor. A few extra weeks can multiply the space requirement, even if annual throughput stays constant.

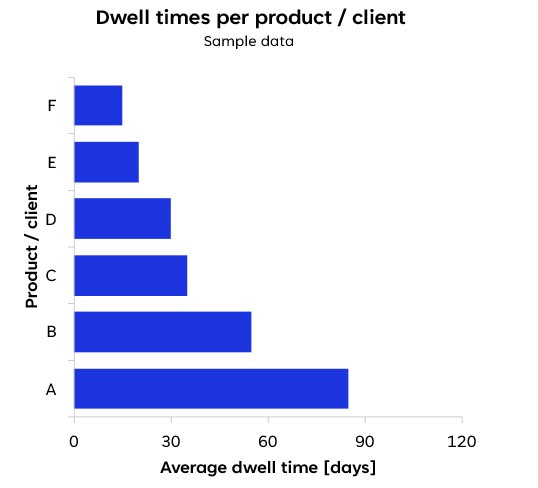

Finally, the terminal’s operational strategy, including whether it primarily serves as a buffer or long-term storage facility, shapes the overall storage needs. In practice, most terminals land somewhere in between: part of the cargo is turned around quickly, while certain grades linger for weeks or months. Balancing those realities is at the core of storage planning.

Figure 2. In reality, most bulk terminals have products that are turned out quickly, while certain products linger for weeks or months

How do you calculate the optimal storage capacity for different bulk commodities?

Calculating optimal storage capacity requires a methodical approach that accounts for commodity-specific characteristics and operational parameters. The fundamental calculation begins with evaluating average throughput, average dwell time, peak factors, and storage commitment levels. Together, these parameters establish the baseline storage requirement.

This initial estimate must then be refined by considering the physical properties of the commodities involved. Bulk density, angle of repose, and safe stacking limits determine how material can be arranged within the available volume, while the choice of handling equipment sets practical boundaries for pile height and achievable storage density. Terminals handling multiple grades or client allocations must also allow for segregation, which often increases the total footprint significantly.

Commitment levels provide resilience for unexpected delays such as extended dwell times or bunching of vessel calls. Finally, sound design incorporates additional allowances for operational clearances, access roads, safety margins, and the possibility of phased expansion. In this way, the calculation becomes a layered process—moving from general parameters to detailed adjustments—ensuring that the resulting capacity is both realistic and resilient under real operating conditions. Designing storage is often like solving a puzzle—fitting many moving parts together so the system works not just on paper but under real operating conditions.

The importance of dynamic validation in storage requirement estimation

Dynamic validation provides valuable insight for storage requirements by examining the complex interactions between vessels, handling equipment, and storage operations over extended time periods. Unlike static calculations, terminal operational models can account for the variability and interdependencies inherent in bulk terminal operations, offering more reliable storage requirement estimates.

Static calculation uses averages and a single peak factor. Real terminals do not behave that neatly:

- Bunching: Two capes arrive back to back while trains are delayed—inventory spikes beyond the planned peak.

- Batch variety: Multiple grades/clients fragment the yard; some slots sit half full while others overflow.

- Downtime: Weather and maintenance reduce reclaim/stack rates at the worst moment.

Example: You have 20,000 m² for three commodities with different arrival patterns. Static calcs based on average flows suggest 18,000 m² is sufficient. A dynamic analysis shows overlapping peaks during harvest and a maintenance shutdown that push demand to 25,000 m² unless the terminal can change scheduling or priorities. Dynamic validation reveals whether to add storage, smooth arrivals, or adjust delivering priorities.

The dynamic analysis approach helps identify potential bottlenecks between waterside operations, storage capacity, and landside logistics, ensuring a balanced system design that optimizes both performance and cost.

How can automation affect bulk terminal storage requirements?

Automation technologies can significantly influence storage requirements for bulk terminals through improvements in stacking density, handling precision, and operational consistency. Automated stacking and reclaiming systems typically achieve higher density storage than conventional equipment, potentially reducing the required storage footprint for the same throughput volume.

- Potential gains: Higher, tighter piles and continuous night/weekend operation can raise effective density and shrink buffer needs.

- Trade offs: More structured layouts, fixed paths and safety envelopes; CAPEX and flexibility considerations.

- Assessment: Compare scenarios (manual vs. semi /fully automated) on both storage footprint and system throughput/integration.

When assessing automation options for bulk terminals, it is important to evaluate not just the direct storage impact but also how automation affects the integrated performance of the entire terminal system.

Key takeaways for effective bulk terminal storage planning

Effective bulk terminal storage planning requires a comprehensive approach that balances analytical calculations with operational insights and future flexibility. The most successful storage designs are those that integrate seamlessly with waterside and landside operations, creating a balanced system that avoids bottlenecks while minimizing unused capacity.

Best practices for storage planning include:

- Develop multiple scenarios based on different throughput projections, commodity mixes and service commitments

- Size with static calculations, then validated with dynamic analysis

- Plan phased development to align capacity with demand growth

- Align storage design with waterside and landside capacities

- Incorporate flexibility for changing commodity mixes and developing technologies

By considering the entire bulk terminal system rather than isolated components, operators can develop storage solutions that enhance overall operational performance and long-term competitiveness.

If you’re interested in learning more, reach out to our team of experts today or Book a Free Consultation

Related Articles

- What infrastructure requirements must ports consider before terminal electrification?

- What grid connection requirements do ports need for large-scale electrification projects?

- How do you phase electrical infrastructure upgrades without disrupting operations?

- What factors determine berth capacity at a terminal?

- How can electrified terminals ensure reliable power supply during high-demand periods?