Can Portwise simulation models be used as digital twins?

Why read this article?

The concept of digital twins is getting more popular every day by companies that are involved in logistics, like we are. The IoT (internet of things) enables communicating between real and virtual systems swiftly and accurately. This makes it possible to apply digital twins in complex logistic systems. Digital twins can help improve performance of systems by dynamically adapting to changes, and by optimising system behaviour.

This article explains the simulation models of Portwise, the possibilities for digital twinning in (container) terminal operations, and whether these two worlds can meet: can Portwise simulation models be used as digital twins?

The world’s most accurate simulation models

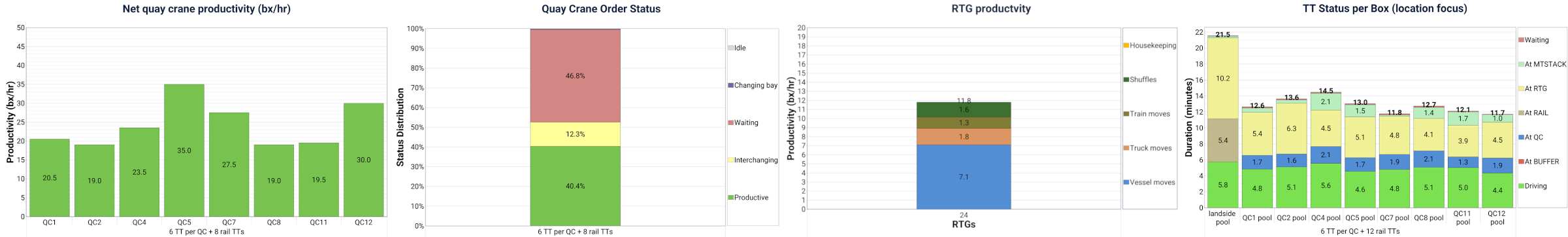

Portwise uses its world renowned simulation models in almost all projects (known as TIMESQUARE and TRAFALQUAR to connoisseurs). These models are considered to be the most accurate digital models of container terminals in the world. They are also used for warehouse simulations, both indoors and outdoors operations. After all, modeling and improving the moving of cargo with machines in congested areas is what we are best at.

What are digital twins?

A digital twin is a virtual representation of an object or system that spans its entire lifecycle, is updated from real-time data, and can send information back to the real physical system to help decision-making. The digital twin should continuously be updated to remain an accurate representation of the real system.

The real system collects data of its current operations, e.g. workload from its operating system, equipment performance from its equipment control system, or weather conditions via sensors. The digital twin can determine and test several strategies to optimise the current operations. Simulation and machine learning can be used in this process. The best expected solution can be applied in the real system. This could for instance be re-assignment of work over other equipment, rerouting equipment, changing storage rules, or energy reducing behaviour.

Simulation models in design studies

Portwise uses its simulation models mostly in design studies for new facilities, or improvement studies for existing facilities that encounter bottlenecks, or that expect radical changes in the future such as different cargo mix, increased volumes, or maybe even scarcity of resources (such as people).

The expected future situation is taken as starting point to configure the models. This ‘situation’ is amongst others defined by the shape of the available land, expected cargo flows, definition of storage area, equipment specs, typical planning and control rules, expected workload via water, road and rail, and many other factors.

The simulation models are used to determine productivity and service levels under different scenarios. Because of the extreme level of detail in the Portwise simulation models, the results of the experiments are proven within maximum 5% inaccuracy factor. Hence, the results of the models can be trusted to define realistic targets and expectations for different possible solutions in designing logistic facilities.

Can Portwise simulation models be used as digital twins?

- The short and honest answer is: no!

- Is that a problem? Again, we say ‘no!’.

Our simulation models provide reliable insights in how a logistic facility can be expected to perform under different circumstances with various equipment numbers, equipment specs, dispatching strategies, yard allocation strategies, etc.

Having these accurate insights in an early stage of the development trajectory of a terminal construction or expansion project helps saving millions of dollars by designing a system that works, and that has enough and not too much equipment in the fleet.

Is a digital twin useful?

Yes, very! A digital twin can help to optimise operations under varying circumstances. It can recognize situations and predict which configuration works well, based on simulation and/or historical data. This should lead to performance increase or cost reduction.

Digital twins can work especially well in systems where standardized products are created on a large scale, e.g. in automobile manufacturing. Operations are standardized and quite reliable in process steps and time.

In container terminals or other large complex logistic facilities, many unforeseen factors play a role in achieving a certain productivity on the site, especially when outdoors. This makes using digital twins less beneficial:

The sheer scale of the facilities alone, can make it close to impossible to run realistic simulations with digital twins in a short amount of time. Fast runtime is needed to provide valuable feedback on time to configure the terminal optimally before the analysed and optimised situation has already passed.

The occurrence of unforeseen factors causes a high uncertainty on whether the predicted best configuration actually leads to the best performing operation.

Nevertheless, we believe that digital twins can help improve operations at complex logistic facilities to some extend, typically in the range of 1% to 5% performance gain or cost savings per shift.

Portwise and digital twins

Portwise does not offer digital twins. We design logistic facilities that work, and that are robust against variations. Tested by the world’s most accurate simulation models for container terminals. Our design team provides a solution that can be expected to operate at good service levels in typical operations without overestimating currently available equipment and software solutions.

Digital twins have started being used in some areas of container terminal operations in recent years. Accurate digital twins for entire terminal operations are not available in the industry yet. At least not according to our high standards of accuracy. Will Portwise ever use its vast knowledge of container terminal design, optimisation and simulation, to develop an accurate digital twin for full scale container terminals? We may yet. We may yet…

About the author Arjen de Waal

Arjen works as manager of the simulation department, simulation expert and product owner of the simulation library at Portwise. Arjen has been involved in many terminal design and optimisation projects all over the globe, and is in charge of the simulation department since August 2011. He is also one of the coordinators and designers of the Portwise Academy, the internal training program.

At TBA – the origin company of Portwise – Arjen was member of the R&D Board, TBA’s internal innovation program. Arjen holds an MSc in Operations Research and Management at the University of Amsterdam.