How to measure container dwell times correctly: common mistakes to avoid

The dwell time of a container is the time that a container has physically stayed on a terminal, and is therefore measured as the difference between the time of leaving the yard and the time of entering the yard. For example, an export container is received from a truck on Monday at 10am in the morning and is loaded to the vessel on Friday at 10pm. This container has a dwell time of 4.5 days.

Dwell times are an important KPI in terminal operations, and are one of the main drivers for terminal capacity. The longer the dwell times, the more space is needed to handle the same volume of containers. Alternatively, given a finite amount of storage space, the longer the dwell times, the fewer containers a terminal can handle. In all capacity projects, dwell times are therefore a key input to the analysis as dwell times directly determine the storage capacity of a terminal.

Dwell times are often also part of commercial agreements between the terminal and shipping lines, covering topics such as receiving windows (how early does terminal allow container to arrive), free time (how many days can container stay for free) and demurrage costs (cost for container to stay beyond free time).

Dwell times are therefore crucial for all parts of the operations. For example: Operations often likes dwell times to be as low as possible to have as much capacity as possible. Commercial departments like to offer increased opening windows and additional free time to please (new) customers.

As dwell times play such an important role, most terminals track their dwell times as one of the key KPIs. As shown earlier, measuring dwell times is a fairly straightforward calculation, but quite often, during the processing / interpretation of operational data into dwell times KPIs, errors are made.

Below three examples of common mistakes in dwell time calculations:

Common mistake nr. 1: the container age is reported as container dwell time.

The container age is the number of days a container is currently on-site. For example at Thursday 10am, our container has an age of 3 days. When it leaves on Friday, it has been there for 4.5 days. The dwell time can only be measured for containers that have left the facility. Therefore, the dwell time is always longer than the container age.

When terminals use container age in their dwell times report, they calculate the average age of all container currently on site. As age is always less than container dwell time, the reported dwell times are too low. This leads to overestimation of terminal capacity.

Common mistake nr. 2: long stay container are excluded

Certain containers can stay a long time. For example, an empty container that sits at the back of a heap pile, and can be on the terminal for more than a year. When reporting on specific time periods (for example a month or one year), only containers are counted that leave the terminal within that time period. Especially when evaluating a shorter period, long stay containers are typically not considered.

Not counting for long stay containers will lead to an under estimation of dwell times, and therefore an over estimation of terminal capacity.

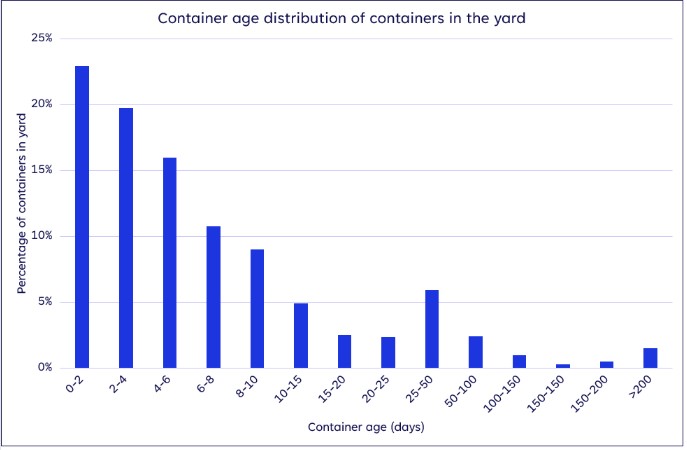

Therefore, understanding how many long stay containers are onsite is crucial to ensure these can be taken into consideration in dwell time analysis. Below graph shows the container age distribution for a terminal. For this terminal ~2% of the containers have been in the yard for more than 200 days, in this case mostly empty containers.

Figure 1: Container age distribution

Common mistake nr. 3: a wrong departure or arrival time is used.

The terminal operating system often tracks different time-stamps related to a container stay. If the wrong time stamp is used, the dwell time will be incorrectly calculated. A common error is that for the departure time, the departure time of the vessel is used. Going back to our example, our container was loaded to the vessel at 10pm on Friday, however let’s say the vessel only departs Saturday morning at 10am (it still had to load other containers between Friday 10pm and Saturday 10am). Using the vessel departure time, leads to a dwell time of 5 days, but actual dwell time of our container is 4.5 days (after 10pm the container no longer occupies space in the yard).

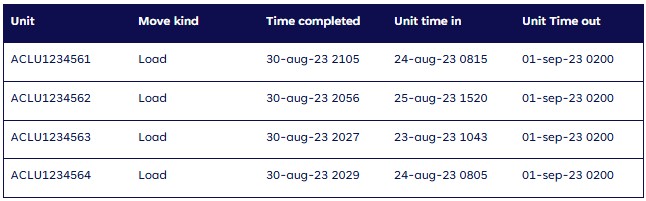

Table 1 shows an example of actual terminal data. The “unit out time” is the same for all load containers (i.e. vessel departure time). The “time completed”, indicated the actual time the container was loaded to the vessel, and therefore is the actual time the container is no longer on the facility.

Table 1: Example of TOS data

In recent studies we have seen that using the vessel departure times increased the reported dwell time for exports by 15 hours (+10 – 15% over estimation of the dwell time).

Concluding

Dwell time KPIs are often taken for granted, without understanding how the dwell times are derived from the system data. As dwell time is key to efficient container terminal operations, influencing both capacity (hence revenue) and operational efficiency (e.g. increased yard occupancy increases rehandling), the terminal management needs to ensure they have the right figures about the dwell time, and they are on top of keeping the dwell time under control.

Take the guesswork out of your container terminal dwell times

Let’s explore how simulation and strategic consulting can help you invest with confidence and build a more resilient, data-driven terminal. Book a Free Consultation